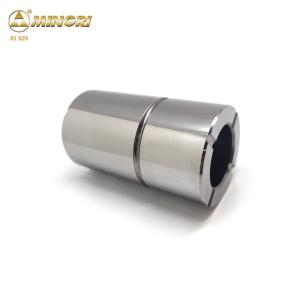

Tungsten Carbide Wear Shaft Sleeve Bush For Submersible Pump

Carbide Nickle Bushing

Character of carbide nickle sleeve

carbide nickle bushing set up by virgin tungsten carbide material.

It’s shows high hardness and bending strength.

That has superior performance on resisting abrasion and corrosion,

which is widely used in many industries

Product name

| tungsten carbide bushing |

Material

| 100% virgin tungsten carbide or carbide nickle |

Color

| grey |

| Standard |

ISO 9001:2008

|

| Grade |

YG6X YG10X YG8 YG15 / YN8 YN11 YN6 ect

|

| Grain size(um) |

0.6/0.8/1.2/2/4

|

Description of carbide nickle sleeve

1. High hard resistance

2. High corrosion resistance

3. Pressured resistance

4. Wear resistance

5. High bending strength

6. 100% virgin raw materials.

7. Various kinds of grades are availalbe based on customer's

application.

8. we have professional advanced production line and inspeciton

equipments to ensure high quality

9. Precision Ground and high polishing process

10. Advanced technology , precise grinding.

Grade | Hardness (HRA) | T.R.S (MPa) | Performance & application recommended |

YG6A | 91.5 | 2400 | Fine grain alloy, good wear resistance. Semi-finishing of chilled

cast iron,

non-ferrous metals alloys, semi-finishing and finishing of hardened

steel, alloy steel. |

YG8 | 89.5 | 2800 | High strength in use, impact and shock resistance higher than YG6,

but wear resistance and

cutting speed comparatively lower |

YN8 | 89 | 2000 | Corrosion Resistant, It widely used in chemical and petroleum pumps |

YG10 | 88 | 2400 | high strength in use, impact and shock resistance higher than YG6,

but wear resistance

and cutting speed comparatively lower. Roughing of cast irons,

non-ferrous metals and their alloys as well as non metallic

materials at low cutting speed. |

YL10.2 | 91.5 | 3000 | Fine grain alloy, good wear resistance. Used for processing hard

wood, veneer board,

PCB, PVC and metals |

Application of carbide nickle sleeve

Carbide nickle bushing applications is wide, which is a device to

protect a class of components.

It is in the actual work and the role and purpose of its

application environment have a great relationship.

Valve applications: bushings be installed in the valve stem cap

trap, in order to reduce the valve leakage, to seal;

Bearing applications:the use of bush to reduce wear between the

bearing and the shaft seat, avoid the gap between the shaft and the

hole increases and so on.

Carbide nickle bushing production and processing of high-strength,

can withstand prolonged load, with high chemical stability, alkali,

alcohol, hydrocarbons, acid, oil, detergent, water (sea water), and

has no smell , non-toxic, tasteless, non-rust characteristics.

Its widely used in petrochemical industry for Submerged Oil Pump,

slurry pump, water pump, Centrifugal Pump,etc.

We also can provide non-magnetic carbide sleeve , it has high

strong anti-corrosion effect